Hanway Revo 2500W Series

Higher Productivity at a More Reasonable Cost

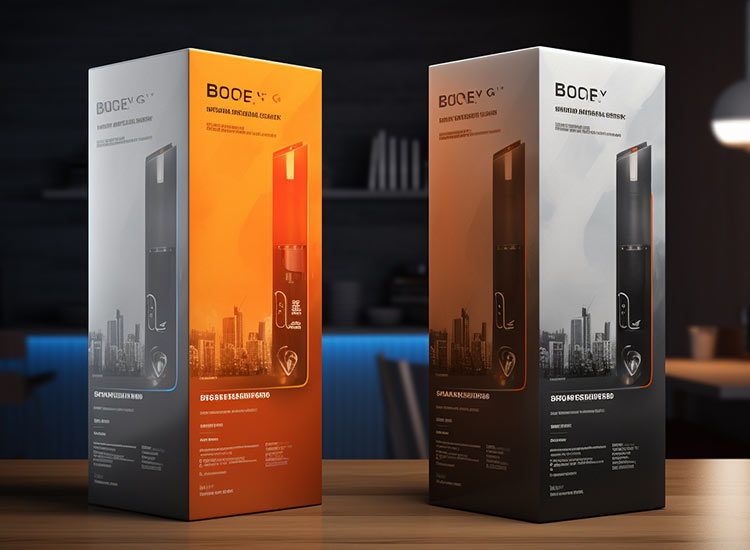

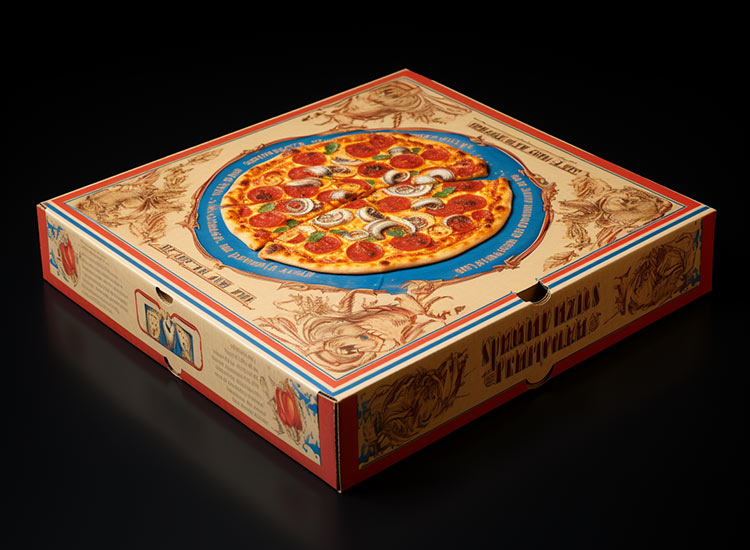

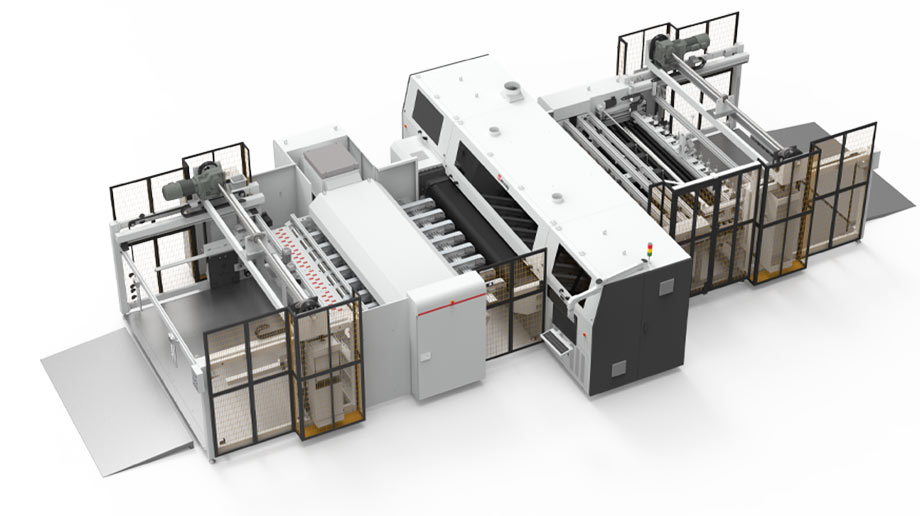

Suitable for all types of corrugated board, the Hanway Revo 2500W series has revolutionized the folding carton industry with automation that brings higher productivity at a more reasonable cost than flexography by minimizing waste and reducing the need for extra labor. Available in two models – the Revo 2500W (In-Line) and Revo 2500W Pro – the series is a highly competitive press that is sure to bring prosperity to those who invest in it.

Both Revo 2500W models feature water-based inks to keep harsh chemicals out of your print operation and support your sustainability efforts. The Revo 2500 Series offers three printing modes: precision, standard and high speed up to 1,400 square meters per hour.

The series is easily installed, operated and maintained. It is the perfect solution for those in search of a stable, long-lasting press that produces high-quality images on folding cartons.

Expert Automation Redefines Package Printing with the Hanway Revo 2500W Series

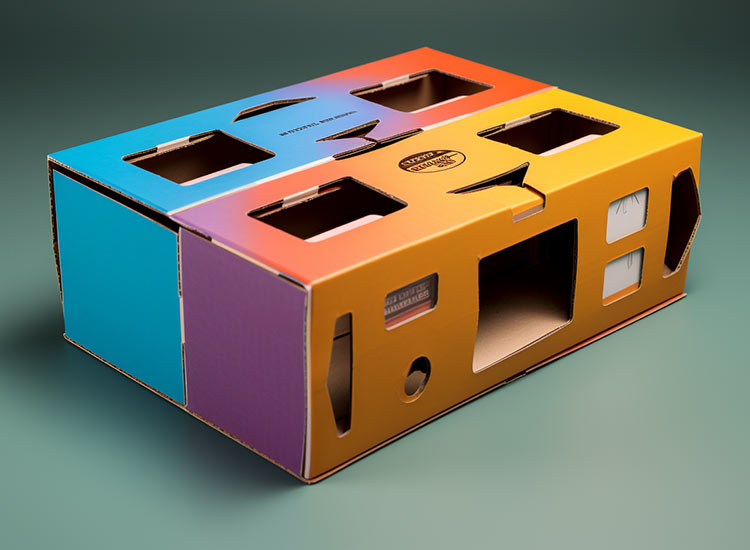

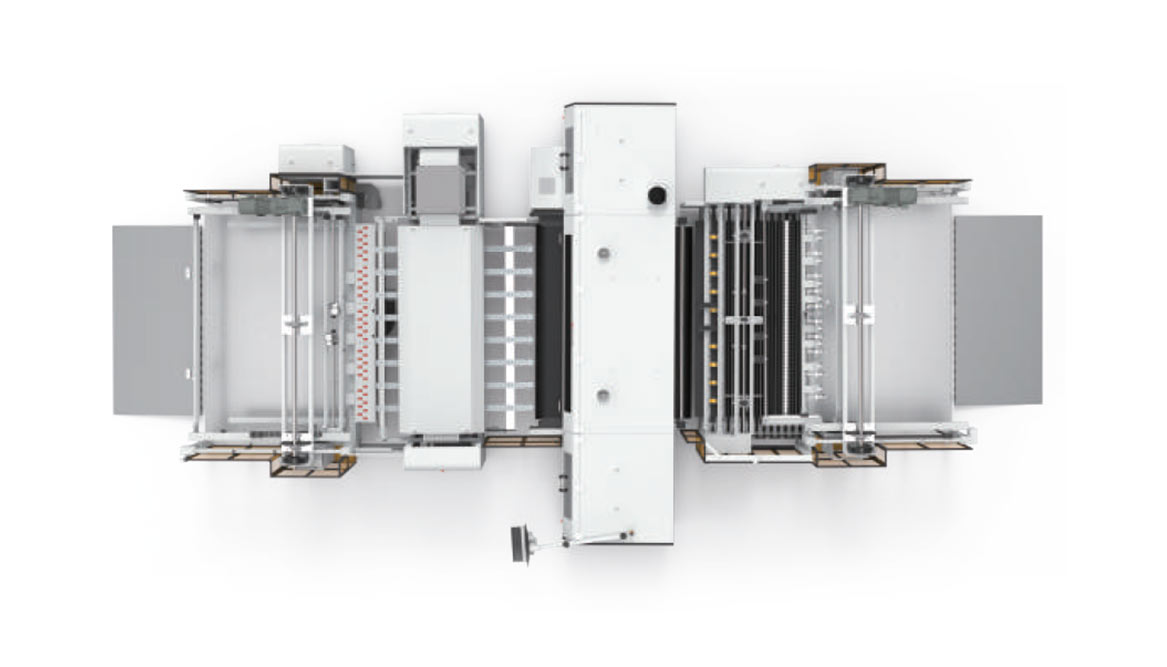

Featuring an all-in-one inline design containing separate varnishing, drying and stacking units, the series is ideal for short- to medium-size print runs and performs exceptionally well on a variety of substrates up to 15 millimeters thick. Its simple architecture and state-of-the-art engineering – including an integrated control interface to quickly set up the machine’s parameters – allow for stability and consistency during all stages of production.

The series is equipped with industrial grade piezoelectric printheads that are arranged in three rows of four. For those who desire six-color printing, two spot colors may be added to each row joining the CMYK colors for a total of 18 printheads. The Hanway Revo 2500W series uses water-based inks and has a sophisticated air-drying system to set each image.

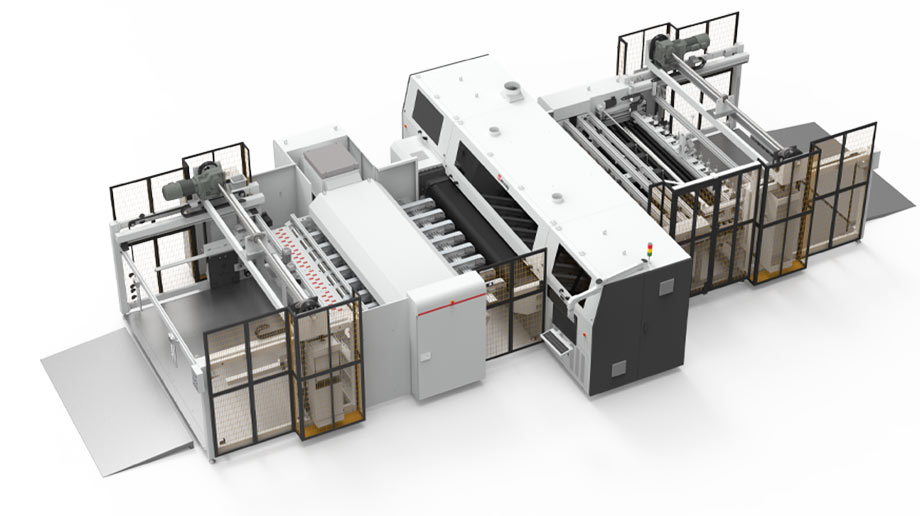

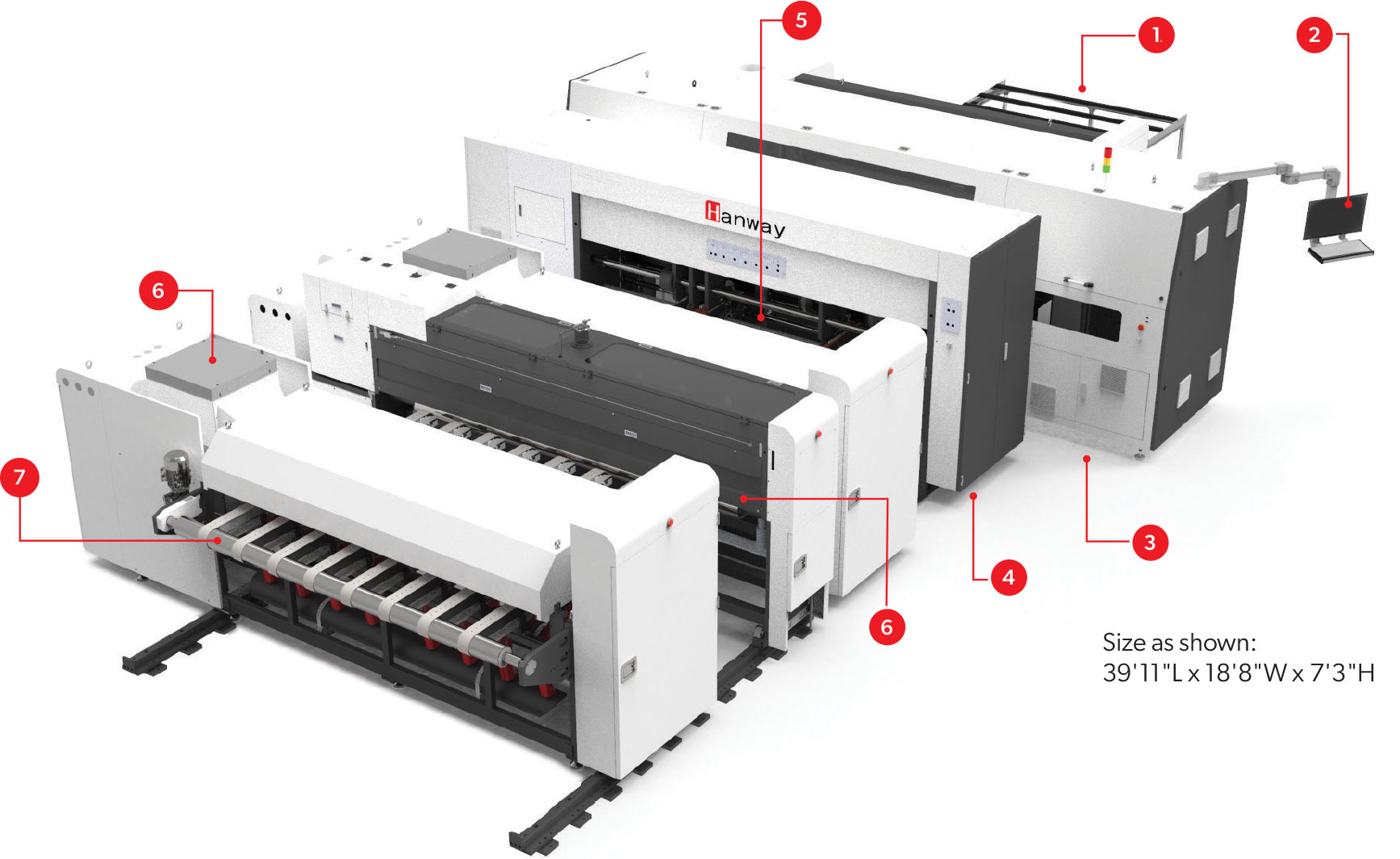

Hanway Revo 2500W

1 Servo platen, bottom feeding, feed system

2 Revo 2500W

3 Drying unit²

4 Varnish unit²

5 Exit to stacking unit

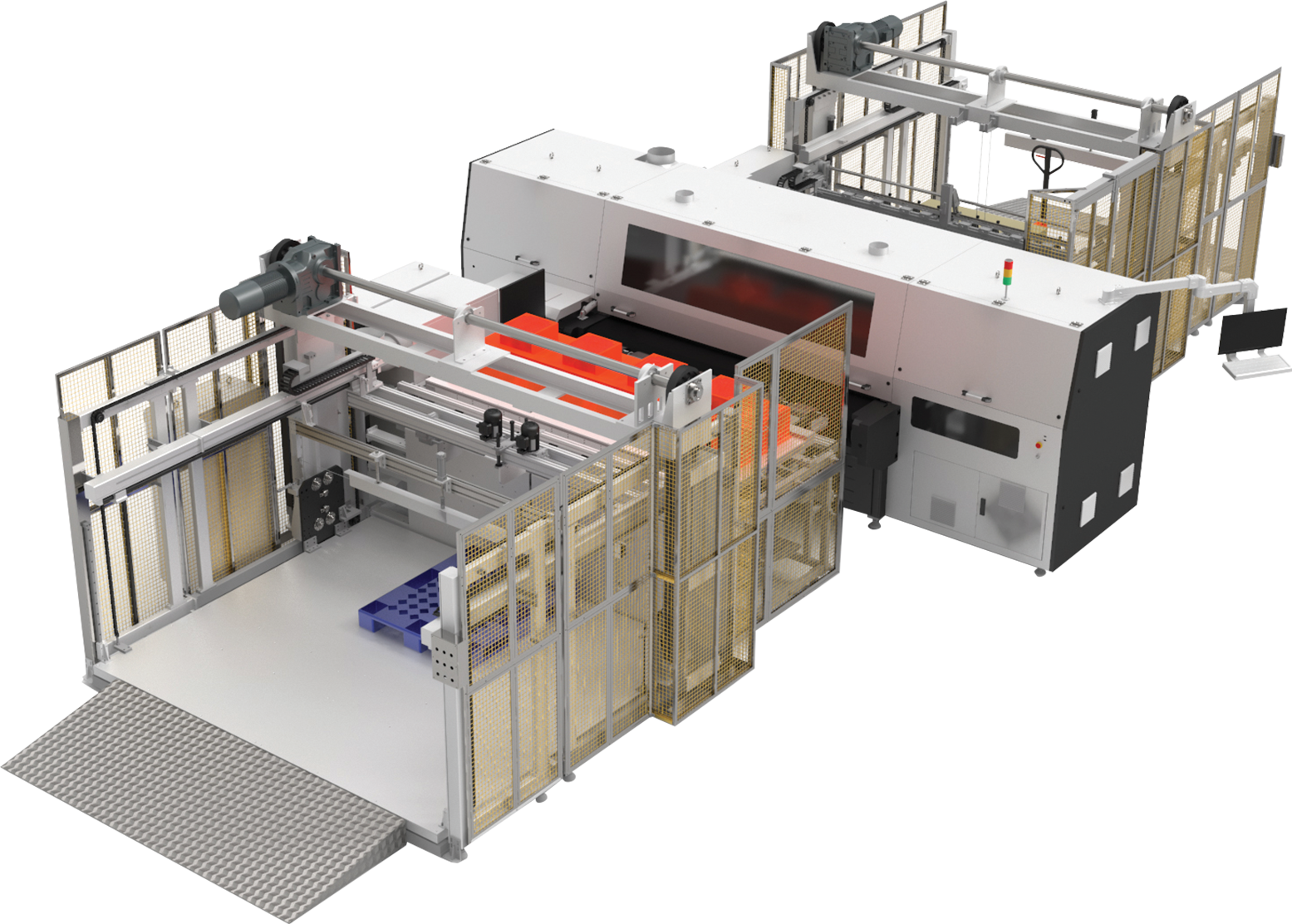

Experience Flexibility in Cardboard Stock with the Revo 2500W Pro

The fully automatic top feeder on the Revo 2500W Pro allows for the smooth transportation of cardboard into the machine while the hanging tray lifts and lowers automatically based on the cardboard’s height. An automatic control function exists for the suction cups to accommodate different sizes of cardboard during the feeding. The press also offers automatic printhead cleaning, which allows printers to not only save time, but also save money by avoiding additional labor and extensive training.

Revo 2500W PRO

Available Options

Drying Unit

- Highly efficient and safe drying system using hot air

- Suitable for various substrates, especially coated paper

- Environmentally friendly zone-control system ideal for transmitting hot air based on the designated print job

Varnish Unit

- Precise coating resolution, volume control and broad application

- Circular, stable coating during production

- Integrated control interface to quickly set up parameters

Stacking Unit

- Fast, efficient, safe mechanism that saves time and labor

- Stable, organized stacking with a simple structure allowing for a broad space

- Integrated control interface to quickly set up parameters

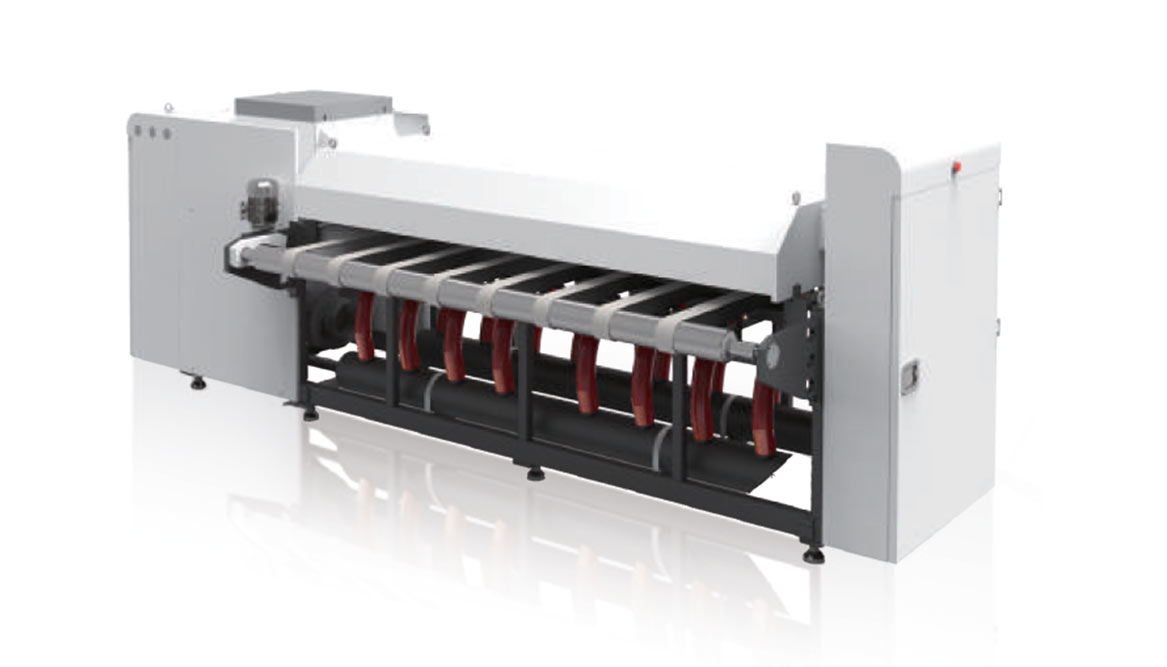

Slotting Unit

- Accurate and repeatable servo-controlled slotting

- Quick and precise regulator-driven slotting size setup

- Accommodates boards 1.5–15 mm thick and sizes up to 2500x4000 mm

Auto Feeder

- Vacuum board feeding system for nondestructive transport

- Automatic control on volume of feed suction cups accommodates multiple sizes of boards

- Hanging tray with automatic lifting and lowering to match height of boards

Specifications

Revo 2500W (In-Line)

Revo 2500W Pro

Revo 2500W (In-Line)

Revo 2500W Pro

| Model | Revo 2500W (In-Line) | Revo 2500W Pro | |

|---|---|---|---|

| Printhead Technology | Kyocera | Kyocera | |

| Configuration | 12 heads in 4-color 18 heads in 6-color | 12 heads in 4-color 18 heads in 6-color | |

| Max. Sheet Size* | 98.4" x 157" 2.5 m x 4 m | 98.4" x 78.74" 2.5 m x 2 m | |

| Speed* | High Quality | 1,693 ft2/hr 157 m2/hr | 1,693 ft2/hr 157 m2/hr |

| Production | 5,550 ft2/hr 511 m2/hr | 5,550 ft2/hr 511 m2/hr | |

| Productivity | Up to 98 coated 4'x8' sheets/hr Up to 172 uncoated 4'x8' sheets/hr | Up to 98 coated 4'x8' sheets/hr Up to 172 uncoated 4'x8' sheets/hr | |

- One year warranty

- Aqueous scanning head

- Kyocera KJ4B greyscale printheads

- Robust industrial design

- Intelligent media feed system

- IR/hot air dryers

- Powerful multi-zoned vacuum system that is adjustable

- Coated or uncoated media print capabilities¹

- Media belt tracking system to ensure stepping accuracy

- Head strike avoidance system

- Automatic printhead cleaning

- White and special color ink capability

- Variable data capability

- Compatible with Onyx, Caldera and other third party RIPs

- One year warranty

- Aqueous scanning head

- Kyocera KJ4B greyscale printheads

- Robust industrial design

- Intelligent media feed system

- IR/hot air dryers

- Powerful multi-zoned vacuum system that is adjustable

- Coated or uncoated media print capabilities¹

- Media belt tracking system to ensure stepping accuracy

- Head strike avoidance system

- Automatic printhead cleaning

- White and special color ink capability

- Variable data capability

- Compatible with Onyx, Caldera and other third party RIPs

¹Coated media printing requires optional dryer

²Optional

³Optional stacker is available

*Meters rounded to the one hundredth decimal