Hanway 2504

High-Speed, Large Format, Single-Pass Corrugated Digital Inkjet Press

Industrial packaging production meets a new era of digitalization with the revolutionary high-speed, large-format, single-pass corrugated digital press. With a modular design that’s easy to install, adjust and maintain, the Hanway 2504 is becoming quite popular in the global market, gaining an exceptional reputation with its amazing productivity, quality and stability.

This digital inline solution can meet the requirements of even the most demanding customers and can assist companies in expanding their markets using variable data capabilities, thus increasing their profits.

Achieve the All-in-One Solution in Package Printing with the Hanway 2504

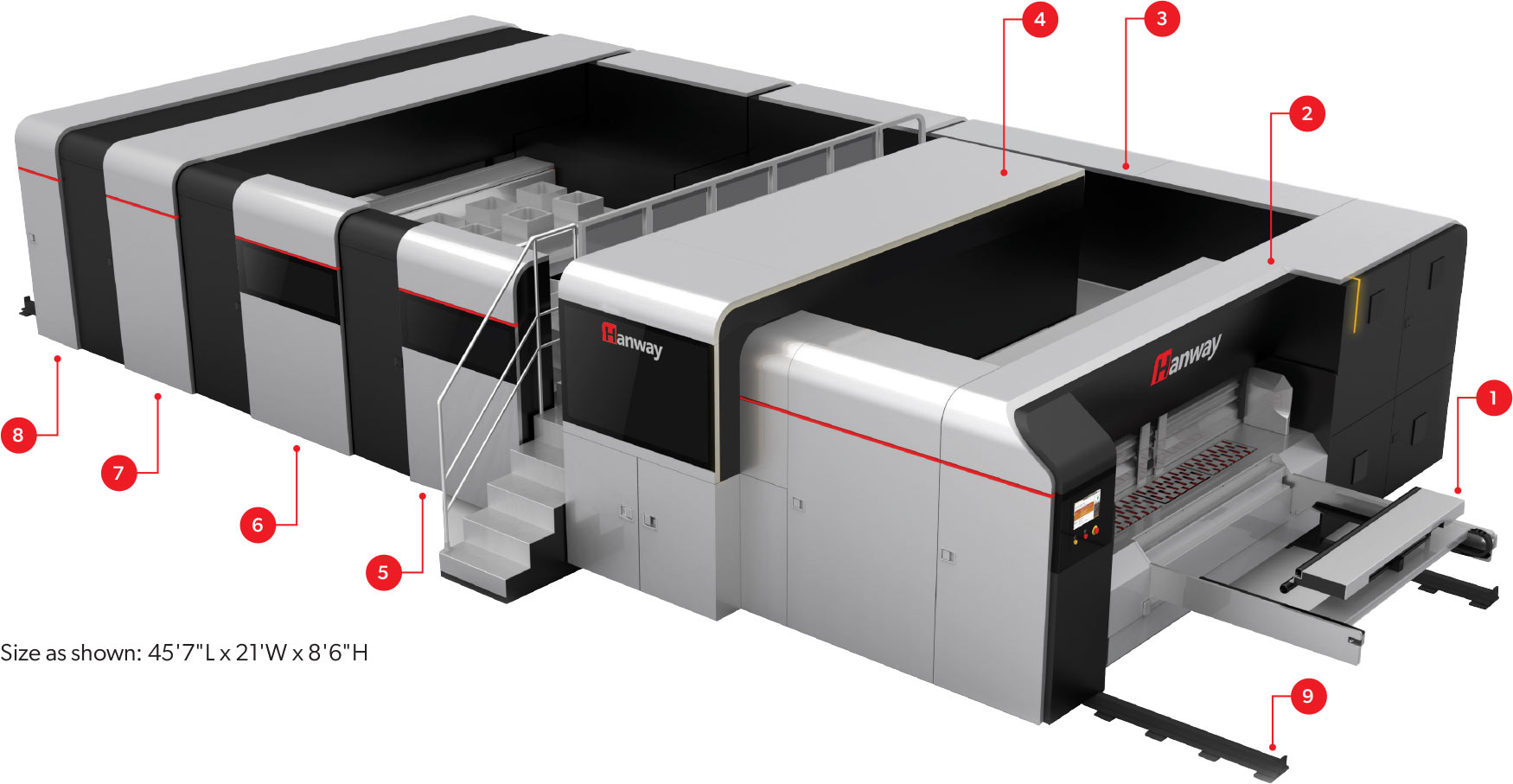

Using an innovative wide-format application design, the Hanway 2504 corrugated press can be equipped with up to 80 industrial-grade piezoelectric Kyocera printheads to produce over 191,000 square feet per hour. Unique to the model is an automatic anti-collision protection system and thermostatic humidity control system to aid in the lifetime of the printheads.

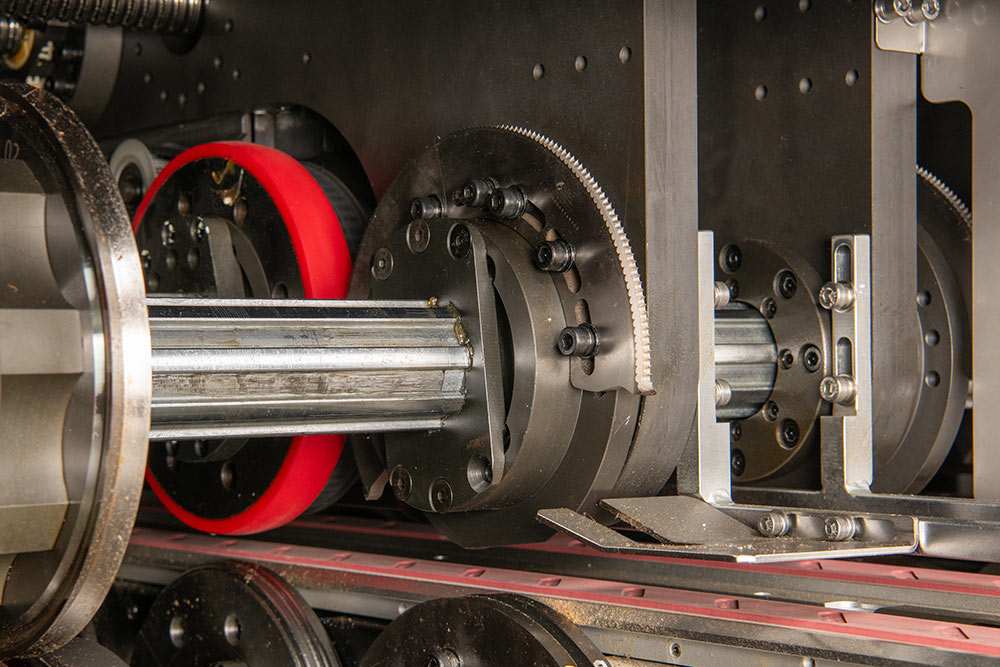

Featuring an advanced linear motor drive for more stable and efficient printing, the Hanway 2504 also offers infrared hot air drying, a warp detection system, automatic printhead cleaning, and a powerful multi-zoned vacuum system that is adjustable. With the ability to use both white and special colors, this machine offers personalized capabilities on uncoated paper.

Utilizing water-based inks, you can reduce your environmental footprint while opening the door to producing packaging compliant with stringent food and pharmaceutical product packaging standards. Plus, with end-to-end workflow solutions from feeding to pre-coating to printing to varnishing to drying to slotting to die-cutting, the Hanway 2504 is the ultimate all-in-one solution for success in variable packaging production.

1 Lead edge feeding system

2 Warp detection system

3 Primer station

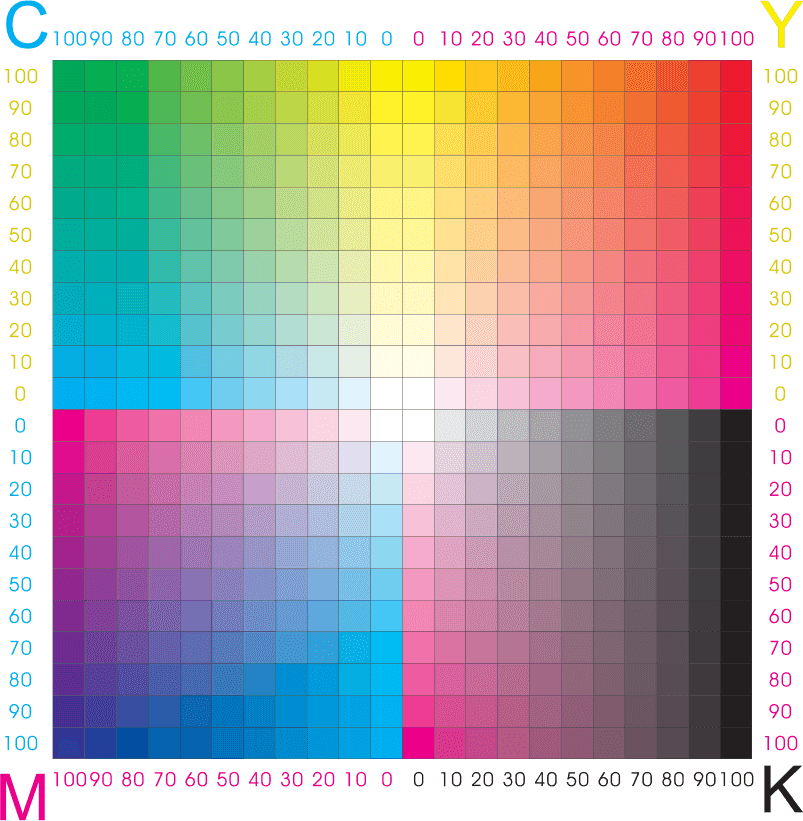

4 CMYK print stations

5 Varnish/coating station¹²

6 IR/hot air dryer²

7 Slotter²

8 Belt exit to offload³

9 Rail system

Opening the Golden Age of Efficiency, Width and Quality

Groundbreaking Applications for Greater Productivity

- No plate-making and no minimum job requirements allow for fast delivery and satisfied customers.

- Savings are acquired in plate-making, labor and storage costs.

- Max. productivity: 17,773 m2/hr

Max. printing width: 2,160 mm

Exceeding Market Demands with Fast Delivery

- One job with the same specifications leads to seamless, continuous production of larger orders.

- Variable-data capabilities offer customized and personalized designs.

- Anti-counterfeiting and tracking methods provide brand protection and security.

Top Performing Hardware & Software

- Modular design makes for a hassle-free installation and easy maintenance.

- Advanced linear motor drive provides stable and efficient printing.

- Humidity control system regulates the temperature of the printheads for improved performance.

- Automatic anti-collision, trolley-based system extends the life of the printheads.

Integrated, Automated & Intelligent Solutions

- End-to-end workflow solution includes feeding, pre-coating, printing, varnishing, drying, slotting, and die-cutting.

- Integration offers substantial labor savings, greater efficiency and better value.

- Manufacturing execution system offers efficient production management.

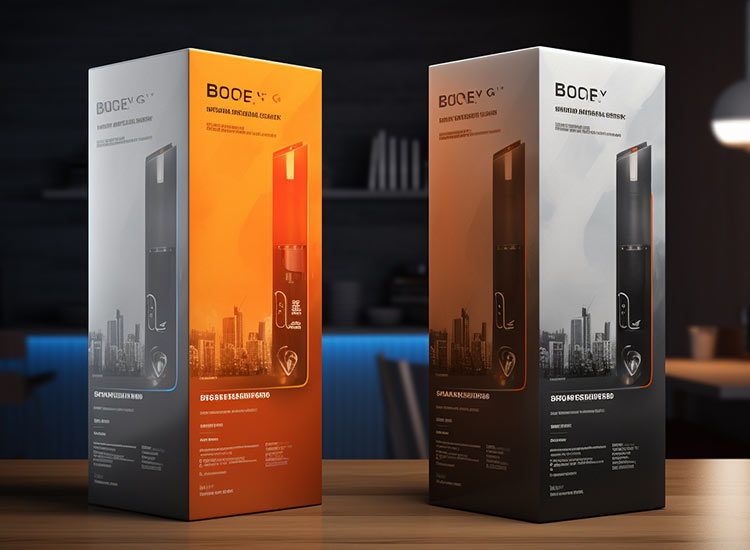

Better Graphic Designs

Unlock the potential for better graphic designs with our printing technology, ensuring your packaging visuals are crafted to perfection with detail and clarity.

Quick Job Changeover

Specifications

| Press | 2504 | |

|---|---|---|

| Printhead Technology | Kyocera | |

| Max. Config. | 80 heads | |

| Max. Colors | 4 | |

| Max. Sheet Size* | 98" x 78.75" 2.5 m x 2.0 m | |

| Linear Speed* | Express | 591 ft/min 180.14 m/min |

| Production | 492 ft/min 149.962 m/min | |

| Quality | 328 ft/min 99.97 m/min | |

- One year warranty

- Aqueous, single-pass head system

- Kyocera KJ4B grayscale printheads

- Robust, industrial design

- Intelligent media feed system

- Powerful multi-zoned vacuum system that is adjustable

- IR/hot air dryers

- Uncoated media print capabilities

- Warp detection system

- Head strike avoidance system

- Automatic printhead cleaning

- Variable data capability

- Compatible with Onyx, Caldera and other third party RIPs

- Thermostatic humidity control system

- One year warranty

- Aqueous, single-pass head system

- Kyocera KJ4B grayscale printheads

- Robust, industrial design

- Intelligent media feed system

- Powerful multi-zoned vacuum system that is adjustable

- IR/hot air dryers

- Uncoated media print capabilities

- Warp detection system

- Head strike avoidance system

- Automatic printhead cleaning

- Variable data capability

- Compatible with Onyx, Caldera and other third party RIPs

- Thermostatic humidity control system

- Automatic anti-collision protection system

¹Coated media printing requires optional dryer

²Optional

³Optional stacker is available

*Meters rounded to the one hundredth decimal