Hanway 1604 HD

Single-Pass Production Meets High-Definition Printing

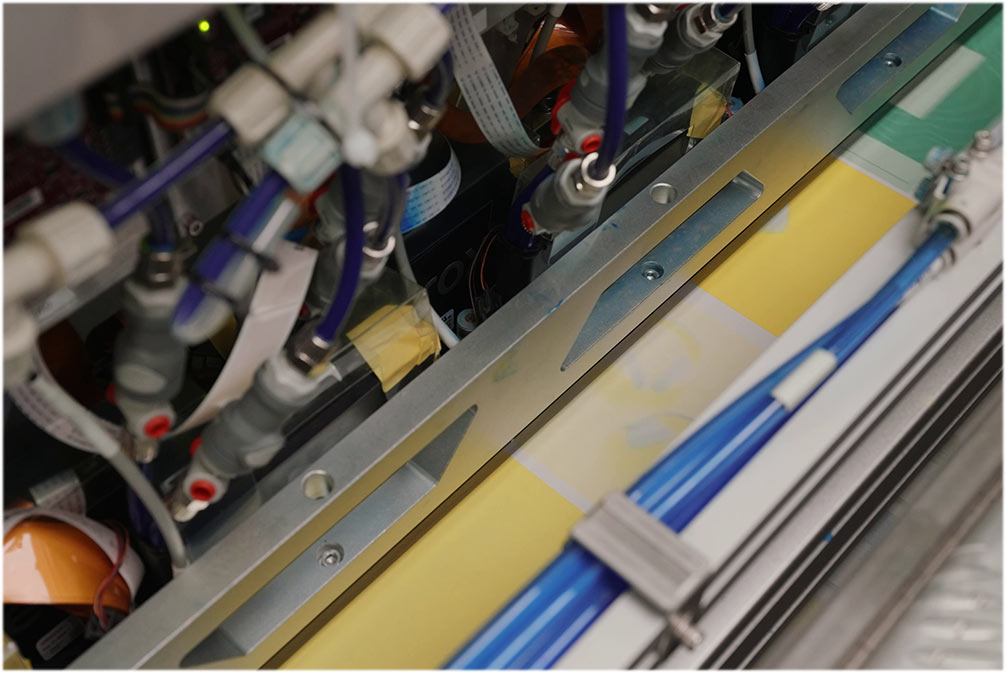

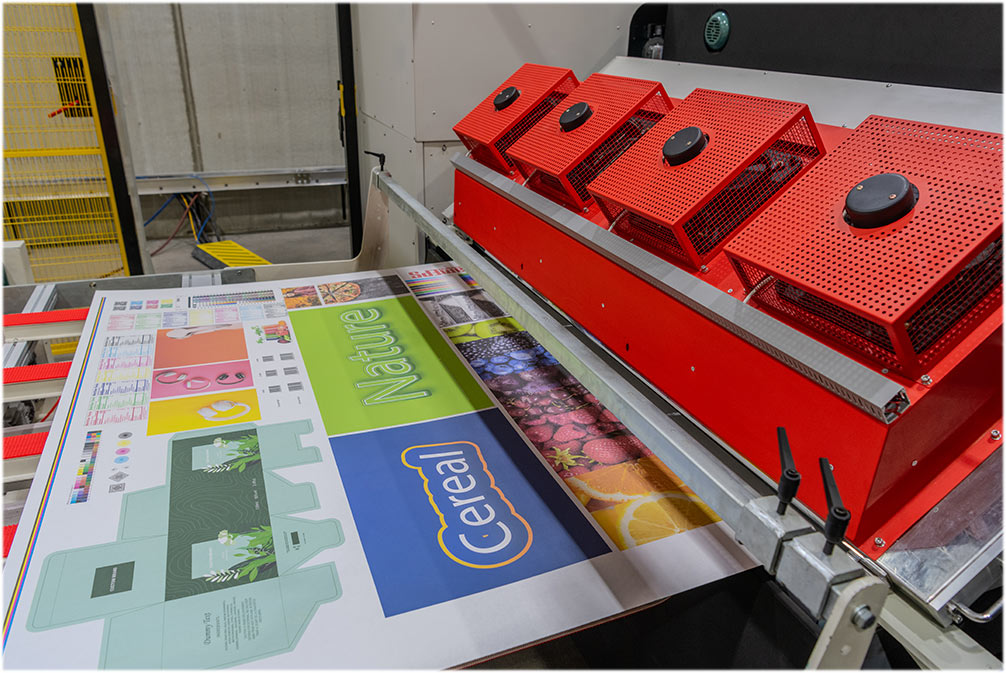

Packaging printers can now achieve high-definition resolution at 1200 x 1200 dpi, on the Hanway 1604 HD 4-color inkjet press. Equipped with features including Drop-On-Demand piezo printheads, automatic printhead cleaning, IR/hot air dryers, closed loop ink supply system, and a warp detection system, this single-pass press uses environmentally friendly water-based inks that are ideal for both coated and uncoated paper.

Take advantage of the optional stacker and discover how easy your production workflow will become. Complemented with an intelligent paper feeding system, the stacker reduces a time-consuming step in the labor process that results in an even greater on-time delivery of your products.

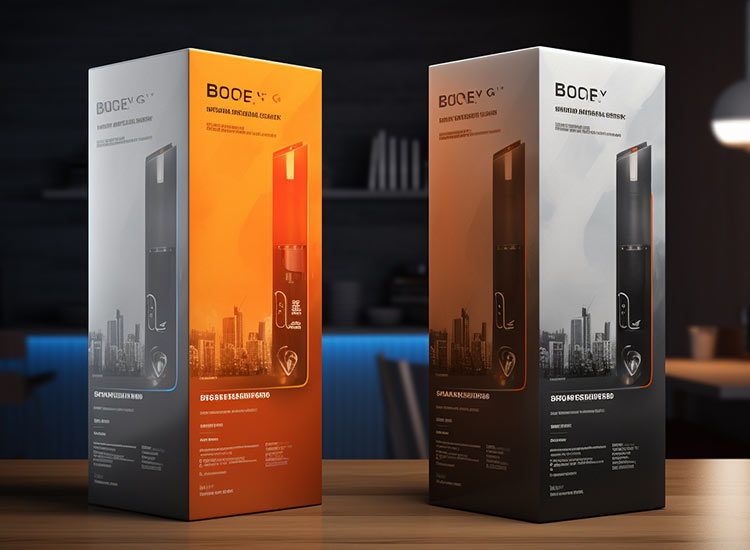

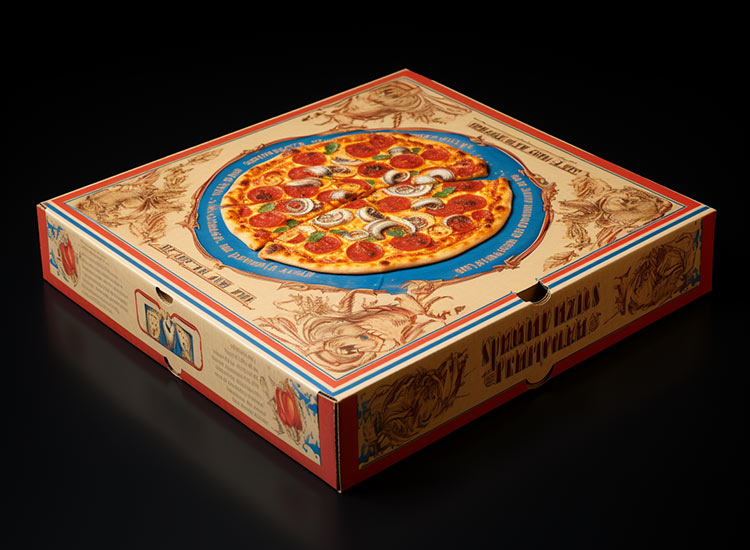

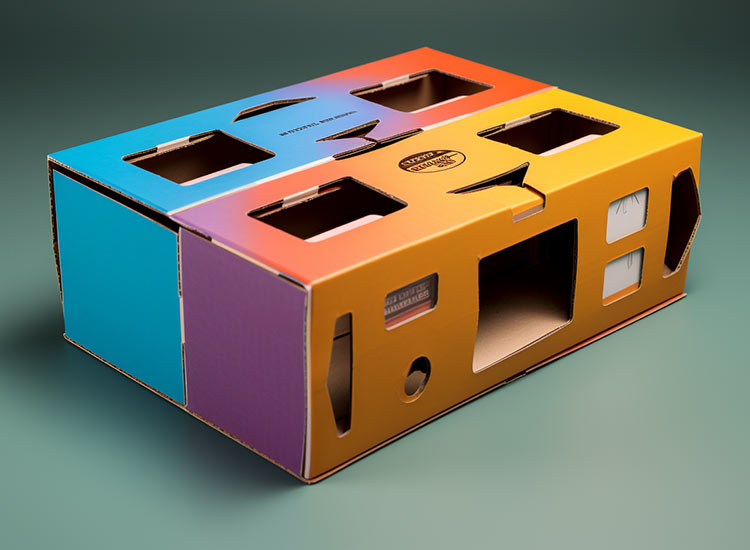

Images So Crisp You’ll Think It Came From a Lithographic Press

When it comes to technology, today’s packaging printers have an array of choices. Now, with the continuing advancement of digital inkjet printing, packaging printers can now produce high-quality images that were once only possible on lithographic offset presses. With the Hanway 1604 single-pass press, you’ll be on your way to producing eye-catching images at exceptional speeds.

1 Lead edge feeding system

2 Warp detection system

3 Primer station

4 1604 - 2 print stations

5 Heating element/hot air dryer

6 Varnish/coating station

7 Hanway single-pass control station

8 Belt exit to offload³

Hanway SP 1604 HD

Single-Pass Production Meets High-Definition Printing

High-speed

Become more competitive by delivering quick turnaround times with a press that offers speeds up to 492 ft/min (150 m/min).

High-quality

Attain highly profitable print requests using four-color printing at 1,200 x 1,200 dpi.

Versatility

Achieve versatility with a press that accepts both coated and uncoated paper.

Personalization

Customize packaging using variable barcodes and QR code printing.

Intelligent

Discover the advantages of the press’s intelligent media feed system.

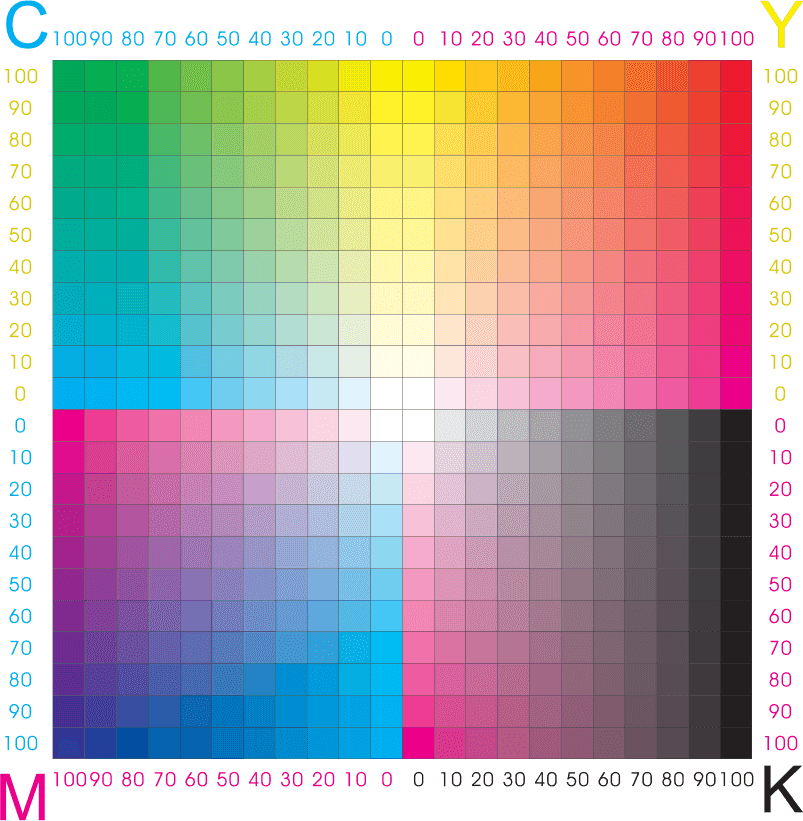

Color Fidelity

Ensure precise color with Drop-On-Demand piezo printheads and offset gamut matching ink set.

Modular

Maximize productivity with quick installation, easy maintenance and efficient output.

Eco-friendly

Achieve sustainability with water-based inks that are 100% free of UV-reactive chemistry.

Excellent Color Reproduction

Discover the outstanding capabilities of our printing technology, delivering excellent color reproduction that brings your packaging designs to life with unmatched vibrancy and precision.

Quick Job Changeover

Specifications

| Press | 1604 HD | |

|---|---|---|

| Printhead Technology | Drop-On-Demand piezo printheads | |

| Max. Config. | 52 heads | |

| Max. Colors | CMYK | |

| Max. Media Size* | 63" x 110.25" 1.6 m x 2.8 m | |

| Linear Speed** | Express | 492 ft/min 150 m/min |

| Production | 250 ft/min 76 m/min | |

| Quality | 164 ft/min 50 m/min | |

- Aqueous, single pass head system

- Drop-On-Demand piezo printheads

- Robust, industrial design

- Intelligent media feed system

- High-power, adjustable, multi-zone vacuum system

- IR/hot air dryers

- Coated or uncoated media print capabilities¹

- Warp detection system

- Head strike avoidance system

- Automatic printhead cleaning

- Offset gamut matching ink set

- Closed loop ink supply system with no waste maintenance

- Compatible with Onyx, Caldera and other third party RIPs

- Aqueous, single pass head system

- Drop-On-Demand piezo printheads

- Robust, industrial design

- Intelligent media feed system

- High-power, adjustable, multi-zone vacuum system

- IR/hot air dryers

- Coated or uncoated media print capabilities¹

- Warp detection system

- Head strike avoidance system

- Automatic printhead cleaning

- Offset gamut matching ink set

- Closed loop ink supply system with no waste maintenance

- Compatible with Onyx, Caldera and other third party RIPs

¹Coated media printing requires optional dryer

²Optional

³Optional stacker is available

*Meters rounded to the nearest tenth

**Meters rounded to the nearest integer