PRODUCTS

The Future of Corrugated Packaging

The transition from flexography to digital inkjet printing represents the future of corrugated packaging that is at the printer’s fingertips. The engineering behind digital inkjet printing technology enables packaging establishments to meet their customers’ demands for quick turnarounds in the form of short- to medium-size runs.

Without the need to change and store plates, digital inkjet presses can easily switch from one job to the next without any hassle and without the need for multiple highly experienced operators.

Functions such as automatic printhead cleaning allow for easy maintenance and fewer disruptions. With variable capabilities, the digital inkjet solution has allowed the corrugated packaging industry to transition from a period of mass production to a realm of mass personalization on demand.

- Environmentally responsible approach to package printing to align with your sustainability goals.

- Water-based inks are UV reactive and chemistry free.

- Achieve a safe and comfortable pressroom environment with non-hazardous inks and the elimination of air pollutants.

- Produce food-safe and medical-grade packaging that meets consumer-safety requirements.

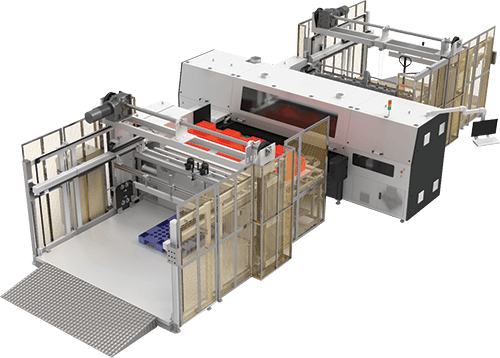

Using drop-on-demand piezo printheads, the single-pass printers are available in two standard size models and one large format model. Each offers optimal color solutions on multiple substrates with a built-in calculator to help regulate your ink costs.

Available in two different models, these high-end machines use water-based ink and air-drying capabilities to achieve exquisite color on packaging.

Contact TeamEPS to discover more about corrugated printing solutions.

CONTACT